3 Advanced Reactor Systems to Watch by 2030

Office of Nuclear Energy April 12, 2021

Move over millennials, there’s a new generation looking to debut by 2030.

Generation IV nuclear reactors are being developed through an international cooperation of 14 countries—including the United States.

The U.S. Department of Energy and its national labs are supporting research and development on a wide range of new advanced reactor technologies that could be a game-changer for the nuclear industry. These innovative systems are expected to be cleaner, safer and more efficient than previous generations.

Intrigued?

Here are three designs we are currently working on with industry partners to help meet our future energy needs in a cost-competitive way.

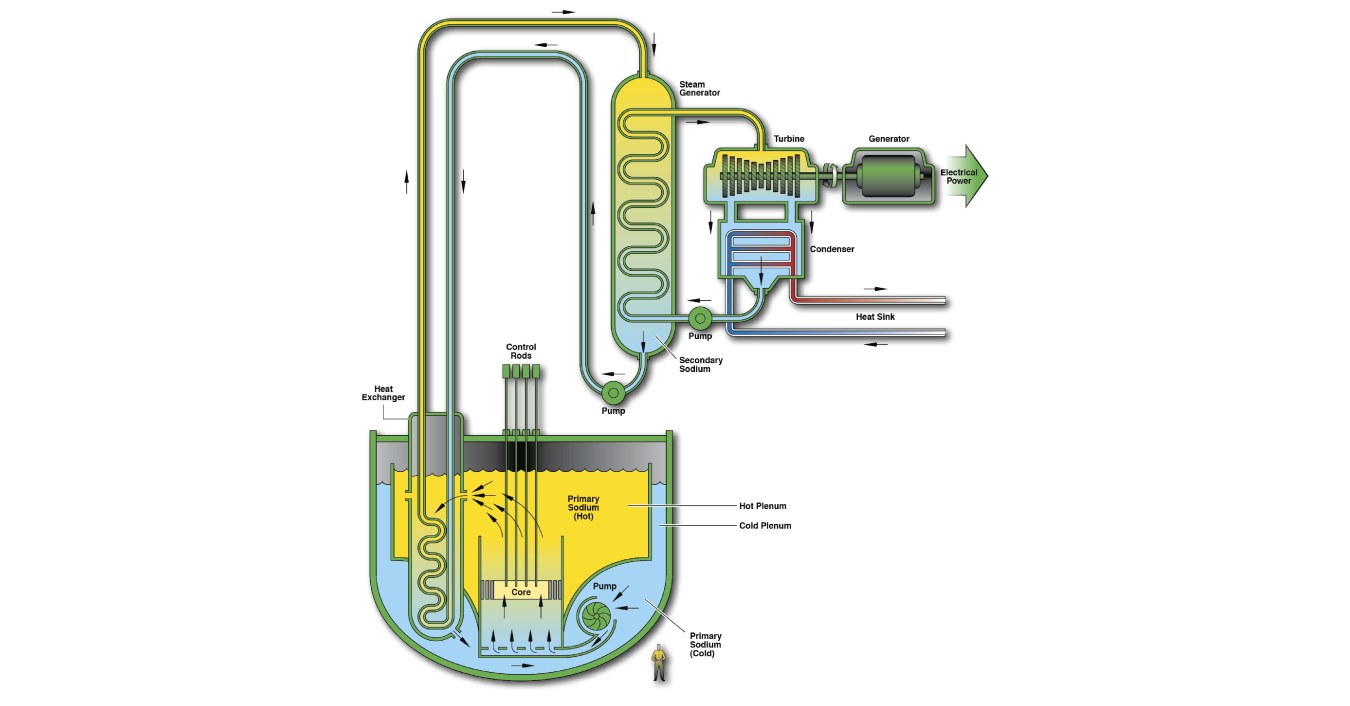

Sodium-Cooled Fast Reactor

SFRs are designed for management of high-level waste and, in particular, management of plutonium and other actinides.Idaho National Laboratory

The sodium-cooled fast reactor (SFR) uses liquid metal (sodium) as a coolant instead of water that is typically used in U.S. commercial power plants. This allows for the coolant to operate at higher temperatures and lower pressures than current reactors—improving the efficiency and safety of the system.

The SFR also uses a fast neutron spectrum, meaning that neutrons can cause fission without having to be slowed down first as they are in current reactors. This could allow SFRs to use both fissile material and spent fuel from current reactors to produce electricity.

Resource: Sodium-Cooled Fast Reactor Fact Sheet

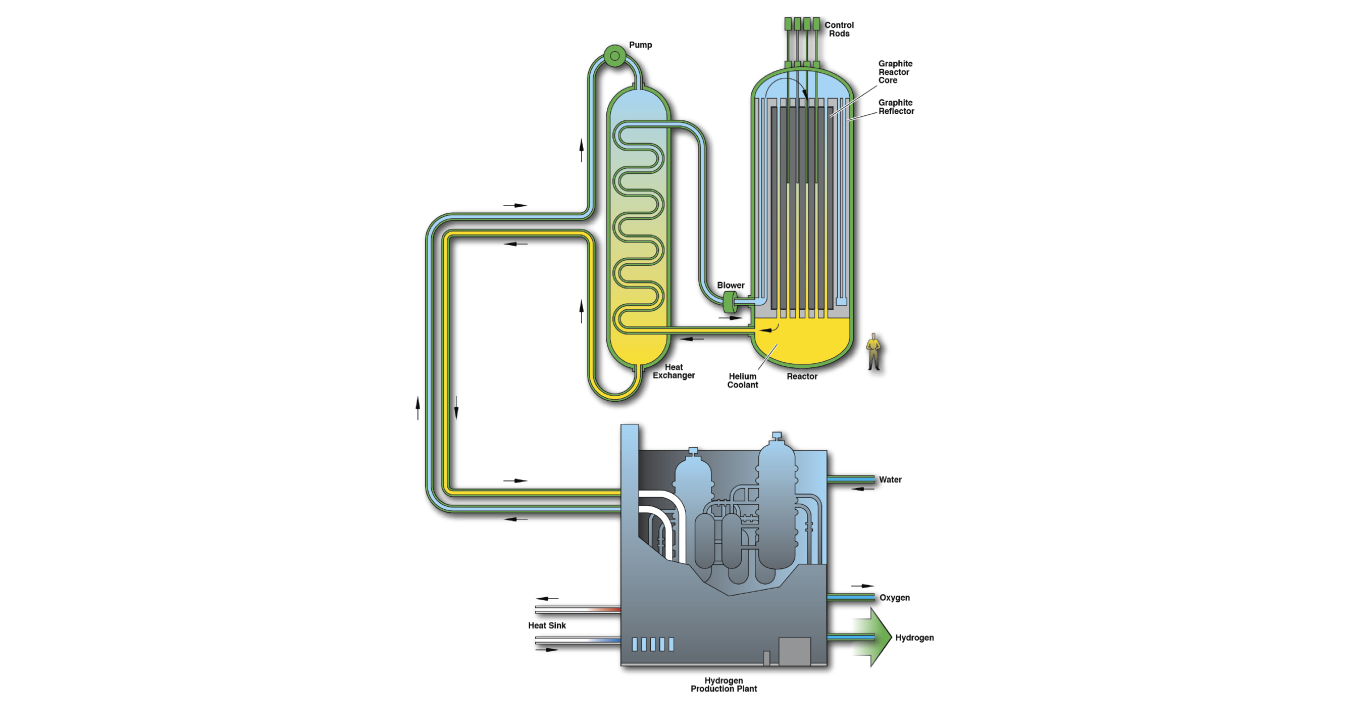

Very High Temperature Reactor

VHTRs offer a broad range of process heat applications and an option for high efficiency electricity production. Idaho National Laboratory

The very high temperature reactor is cooled by flowing gas and is designed to operate at high temperatures that can produce electricity extremely efficiently. The high temperature gas could also be used in energy-intensive processes that currently rely on fossil fuels, such as hydrogen production, desalination, district heating, petroleum refining, and ammonia production. Very high temperature reactors offer impressive safety features and can be easy to construct and affordable to maintain.

Resource: Very High Temperature Reactor Fact Sheet

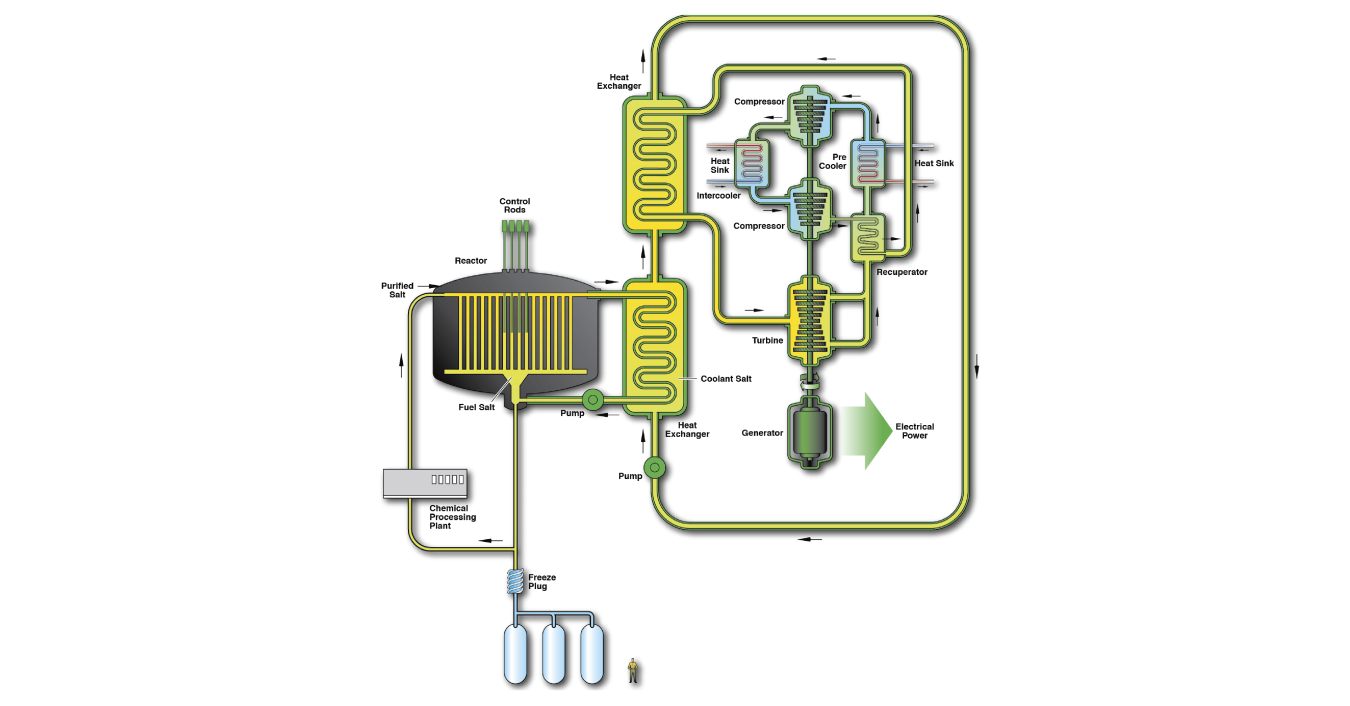

Molten Salt Reactor

MSRs have a closed fuel cycle that can be tailored for the efficient burn up of plutonium and minor actinides. Idaho National Laboratory

Get the latest news, blogs and videos from the Office of Nuclear Energy in your inbox.

Molten salt reactors (MSR) use molten fluoride or chloride salts as a coolant. The coolant can flow over solid fuel like other reactors or fissile materials can be dissolved directly into the primary coolant so that the fission directly heats the salt.

MSRs are designed to use less fuel and produce shorter-lived radioactive waste than other reactor types. They have the potential to significantly change the safety posture and economics of nuclear energy production by processing fuel online, removing waste products and adding fresh fuel without lengthy refueling outages.

Their operation can be tailored for the efficient burn up of plutonium and minor actinides, which could allow MSRs to consume waste from other reactors.

The system can also be used for electricity or hydrogen production.

Resource: Molten Salt Reactor Fact SheetOffice of Nuclear Energy

Recap

Generation IV nuclear reactors are being developed through an international cooperation of 14 countries—including the United States.